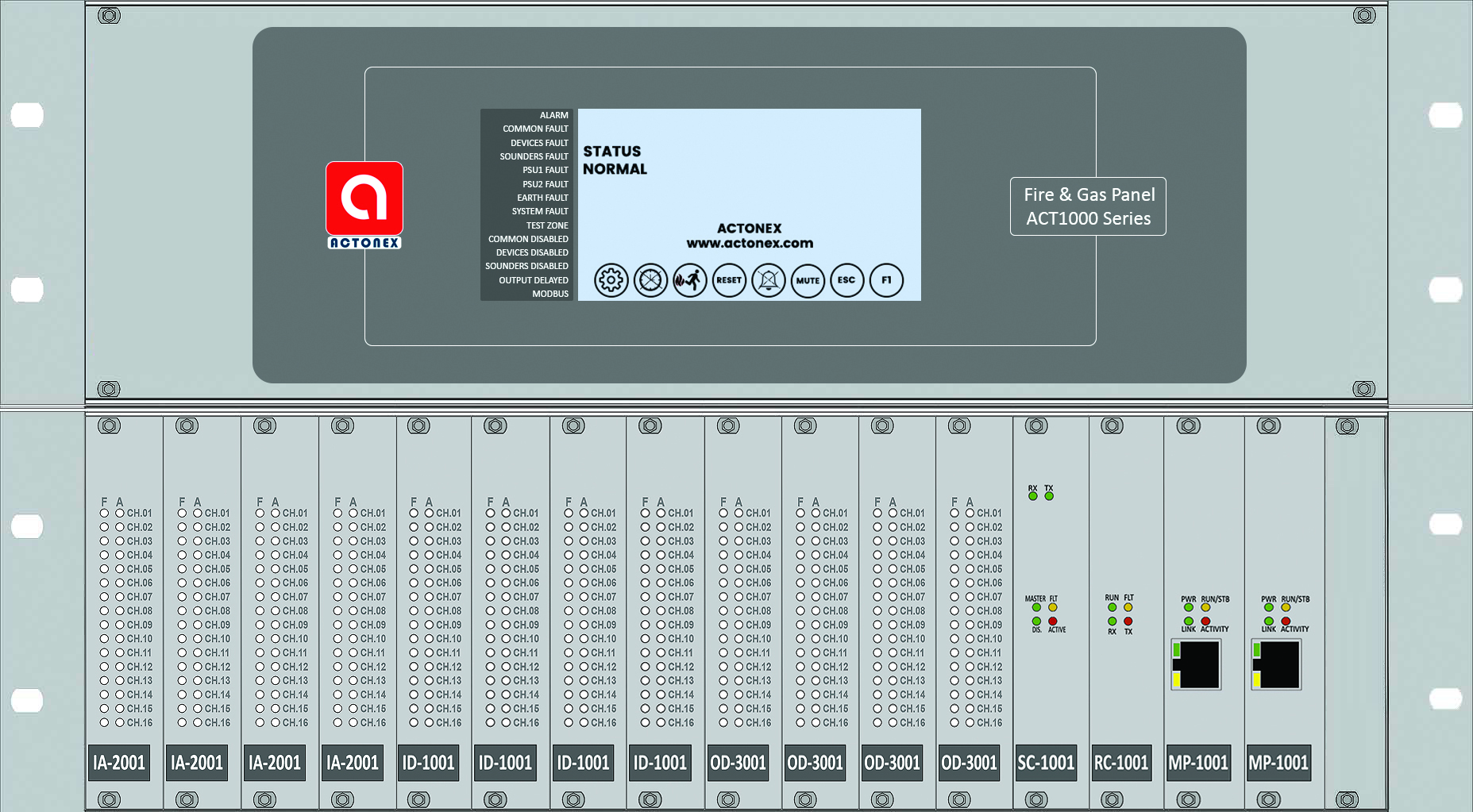

Display Model

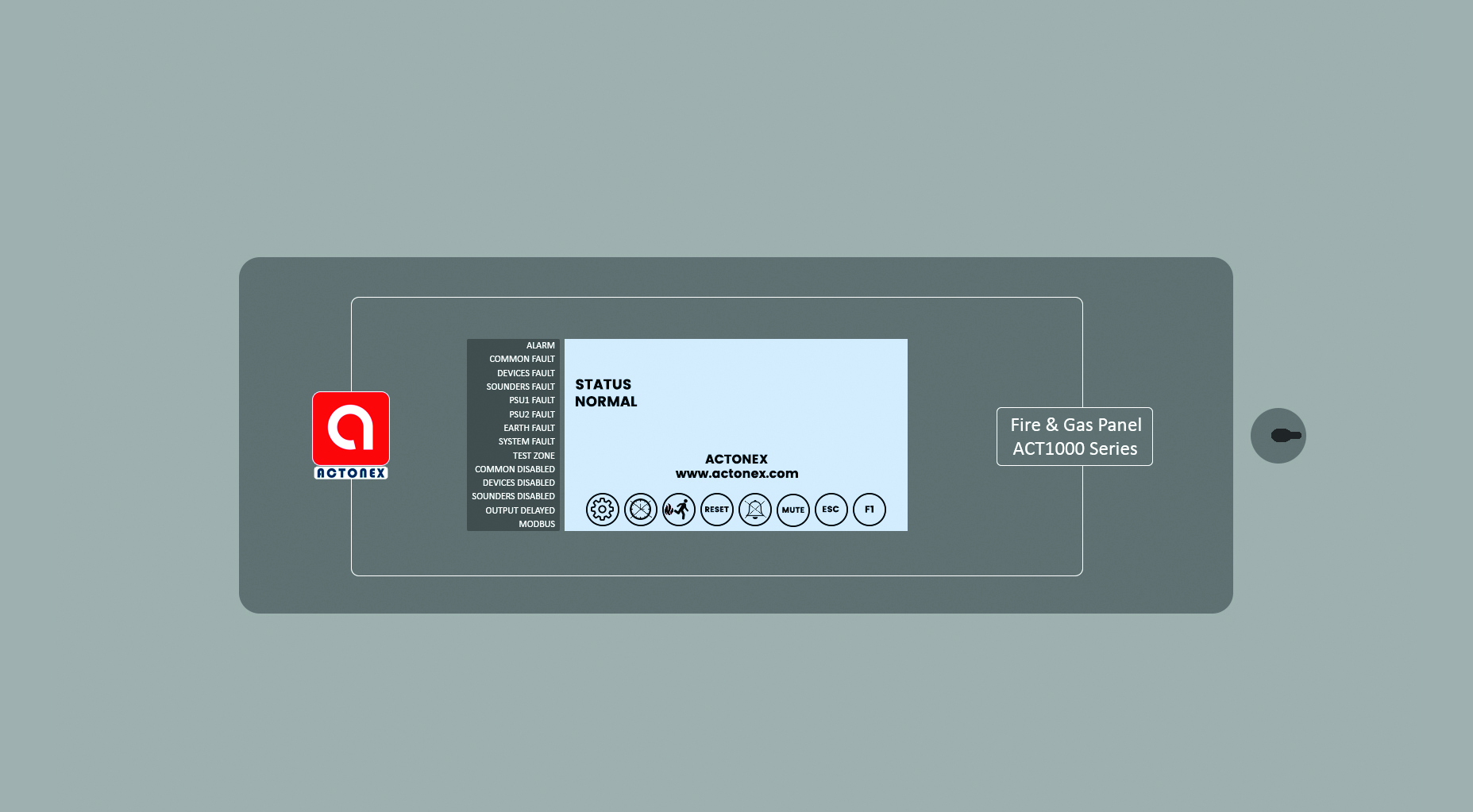

HMI Model

Introduction to ACTONEX F&G System

ACTONEX is an SIL3 F&G system that designs and manufactures automated safety solutions. Everything we do, think, and create aims to help you achieve safety. The result of this philosophy is solutions that provide maximum safety and uninterrupted plant operations.

Application and Installation of ACTONEX Models

ACTONEX models serve medium to large applications. The modular unit supports the installation of up to eleven 19-inch, 3-unit high anodized aluminum racks. We install the racks in a steel cabinet with a revolving rack and acrylic glass door. The first rack contains the operator interface display and keyboard. Additional racks house one or two CPUs and 15 slots for I/O card installations.

System Configuration

We configure the system based on the type and number of components required to protect the system. Each card in the rack connects to field devices via prewired connectors attached to electromechanical terminal blocks.

Efficiency and Performance Benefits of ACT1000 Solutions

ACT1000 solutions increase your efficiency by:

– Avoiding over- and under-dimensioning

– Maximizing plant uptime

– Reducing investment and lifecycle costs

– Providing future-proof, lifetime flexibility

– Offering superior ease of use

Integration with DCS & ESD Systems

Full integration with DCS & ESD operating and monitoring functions is a key feature of ACTONEX As an sil3 F&G detection system, ACTONEX integrates seamlessly with all leading Distributed Control Systems (DCS) and Emergency Shutdown (ESD) systems via industrial protocols.

Self-Diagnostic Capabilities

Self-Diagnostic:

In case the SIL3 F&G system detects an internal fault, then the affected module can be quickly replaced during operation. Moreover, this ensures minimal disruption to the process. The new module automatically synchronizes with the operative modules, importing the parameter settings and user program from the functioning processor module. This feature offers additional benefits for users:

– Reducing the need for a large spare parts inventory

– Eliminating the need to search for correct software versions

– Simplifying the replacement process for processor modules without requiring a computer connection.

Proof Testing According to Industry Standards

Proof Test:

According to IEC 61508 and IEC 61511, every safety system must undergo a proof test at regular intervals. This test helps identify any faults, ensuring the system can be restored to perform its intended function. For ACTONEX semiconductor modules, the proof test interval is one year. For relay modules, the current and switching cycles are measured to assess the relay’s status. Depending on the load, the relay module can continue operating after the proof test without needing replacement.

ACTONEX (F&G Control Panel) can undergo a proof test by testing the entire safety circuit. In practice, while field unit inputs and outputs require a shorter testing interval (6-12 months), on the other hand, the ACTONEX F&G detection system controller demands longer intervals.

Transparent and Fast Diagnostic Features

Transparent, Fast Diagnosis:

The system regularly checks its functionality using self-diagnosis and provides detailed information via LEDs. These LEDs display the full range of operating statuses, allowing you to quickly determine if redundant parts are available, if the system bus is functioning correctly, if an internal fault has been detected, or if there is a fault in the field. Since more than 90% of faults occur on the field side, ACTONEX helps quickly detect issues like short circuits and wiring breakages by indicating the faulty channel.

The fully integrated engineering tool offers online diagnostic features, providing detailed information about operating statuses over time. You can connect a computer running diagnostic software at any point in the network, speeding up fault detection.

High-Performance System Components of ACTONEX (ACT1000)

System Components:

ACTONEX (ACT1000) defines a new performance category with its high-performance system components and intelligent architecture, including:

– High-performance RISK processors for fast calculations

– Simultaneous processing of analog and digital signals in the I/O modules

– A system bus with a 100 MBit/s transmission speed

These features deliver impressive performance, including the capability to handle up to 896 I/Os per cabinet with a cycle time of just 800 ms for 896 I/Os (half analog, half digital).

Key Industries Utilizing F&G Detection Systems

F&G detection systems are crucial in industries with a high risk of fire and gas leaks. ACTONEX control panels serve the following industries:

– Oil and Gas

– Power Plants

– Chemical Industry

– Marine Industry

– Metals and Mining

– Aerospace and Defense

– Energy Production and Distribution

– Automotive and Aerospace Manufacturing

– Hospitals and Medical Centers

– High-Rise Buildings and Commercial Centers